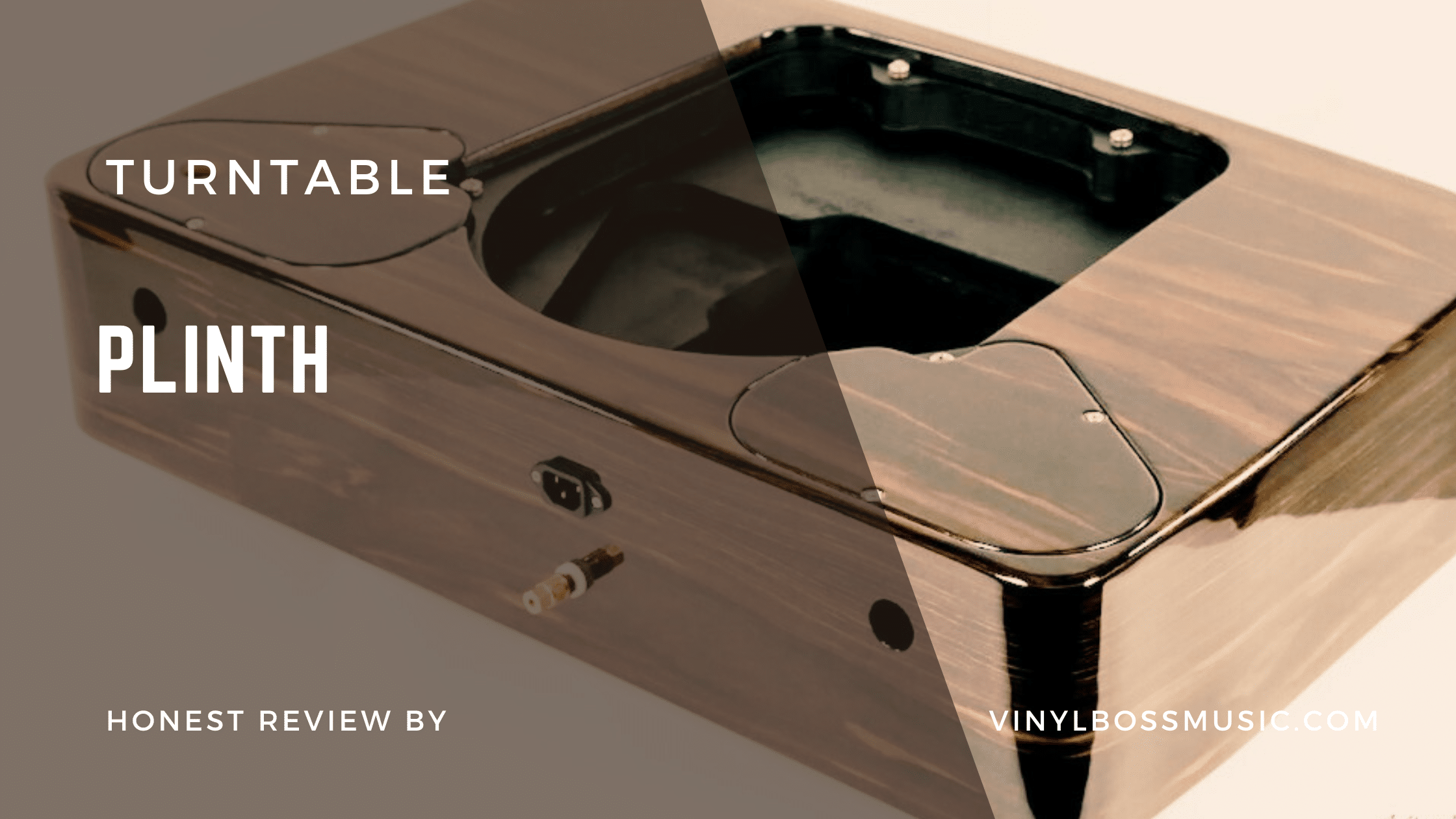

So you’ve owned a turntable for some time now. Great! The deck and its components have served you well so far, but you just feel you need another plinth. It could be that you want to enhance the turntable’s appearance or sound performance. Whatever the reason, this article is for you.

Where to Buy Turntable Plinth?

Before we go any further, it would be nice to know the brands that sell turntable plinths. I have compiled a list for you below:

Amazon

The platform features a range of turntable plinths at different prices, depending on the brand. There are also various materials, shapes, and designs to choose from.

Pro-Ject

Pro-Ject mainly offers replacement plinths for their turntable models. You can purchase a plinth through the company’s official website or authorized dealers.

eBay

Turntable plinths sold on eBay vary widely in terms of brand, condition, material, and design. Options range from cost-friendly to high-end and collectible models.

U-Turn Audio

On the U-Turn Audio platform, you’ll find turntable bases built from acrylic, MDF, plywood, etc. These plinths are often crafted to complement their turntable models and are an ideal choice for audiophiles who want reliable performance at an affordable price.

Etsy

With Etsy, you can choose plinths created by independent artisans and materials. Like the other platforms, these plinths vary in designs, materials, and styles, enabling you to find distinctive options that match your preferences.

Functions of a Plinth

The plinth plays an essential role in the turntable structure. To be specific, it offers:

- Stability: The plinth holds everything together, stabilizing the entire turntable structure.

- Damps vibrations: It also absorbs and gets rid of external vibrations. As a result, the stylus can track your groove without unnecessary interference.

- Distributes weight: The plinth ensures that the turntable’s weight is evenly distributed as well. This averts any wobbling that could interfere with sound quality.

Types of Turntable Plinth Designs

Each turntable plinth design is described in detail below to help you decide the ideal one:

- Wooden turntable plinth: If you have a special love bond with wood, then this plinth might be a great choice. Nevertheless, the quality and appearance can vary depending on the construction method, thickness, and type of wood used. Wooden plinths offer a warm and natural feel and dampen vibrations for enhanced sound production.

- Custom turntable plinth: As the name suggests, a custom plinth is designed according to the user’s specifications. The materials used and design elements are integrated as indicated by the client.

- Custom mame turntable plinth: This is a miniature version of the standard plinth many are used to. In most cases, it’s built with careful attention to detail while mimicking the major features of the usual plinth. Despite its tiny size, a custom mame turntable plinth retains the level of craftsmanship and quality as its larger counterpart.

- Stone turntable plinth: If you love style and elegance, the Stone turntable plinth offers both. It is made up of stone like granite or marble, giving the base a distinctive and lavish aesthetic. The material also enhances the plinth’s stability and durability.

- Phenolic turntable plinth: Built from a thermosetting resin, the phenolic plinth is moisture and heat-resistant. It’s also designed to control vibration and offer more stability to the entire turntable. These features contribute to clearer and more accurate sound production, enhancing the listening experience.

- Garrard turntable plinth: This plinth offers a stable foundation for Garrard turntables, reducing vibrations for better sound quality.

- Dual turntable plinth: This features two separate sections within a single structure. One section includes the motor and drive mechanism, while the other supports the cartridge and tonearm.

- Wooden hi end turntable plinth: The plinth is constructed from premium wood materials to provide visual appeal and acoustic isolation, improving the performance of high-end turntables.

What Makes a Good Turntable Plinth?

You can easily be blown away by a turntable’s overall look and forget to check the quality of the plinth. In any case, a good plinth is vital to the turntable’s performance and prolonged shelf-life. So, what should you look out for?

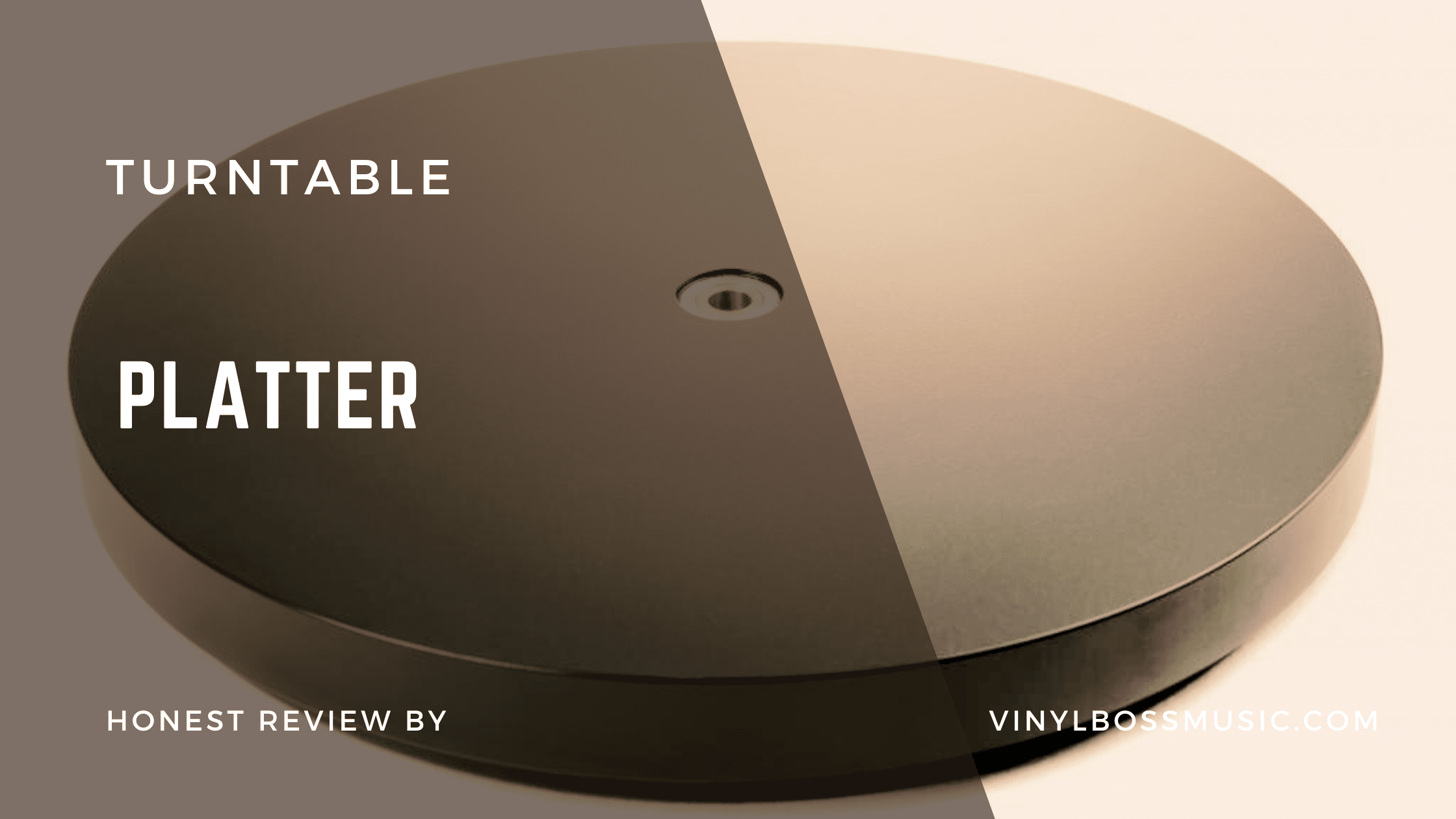

Material

Plinths made of acrylic, metal, or dense wood can be a good choice. Each material provides unique characteristics, including exceptional damping characteristics, clarity, transparency, etc., to ensure you enjoy quality sound.

Resonance Control

It’s crucial to keep off unwanted vibrations, so it’s advisable to go for plinths that keep resonance in check. Such plinths may incorporate damping layers like rubber or sorbothane pads to help reduce resonance. Internal bracing or reinforcement structures may also be added within the plinth to make it stiffer and more stable, eventually reducing unwanted resonance.

Isolation

Isolation from external vibrations is essential in averting interference with the playback. Having this in mind, search for plinths with isolation feet or other features that seek to create a barrier between the plinth and its environment to minimize external vibrations.

A Guide Into a Turntable Plinth DIY Project

Creating a DIY turntable plinth can be fun and a great opportunity to learn and appreciate the work that goes into making one. Here is a turntable plinth template to get you started:

- Plan. Consider the dimensions of your turntable, the materials you will use, and how you want the plinth to look.

- Collect materials. Now that you have the plinth structure in mind, collect all the necessary materials, such as plywood, metal sheets, or MDF. You may also require some tools for assembly, like bolts, cutting tools, measuring tape, an adhesive, screws, and bolts.

- Cut and shape the base. Cut your preferred material into the shape you want while taking measurements to ensure the plinth has all the correct dimensions.

- Assemble. Put up the turntable together based on the design using bolts, screws, and glue. It’s recommended you add some feet for decoupling and stability.

- Finishing touches. You can smooth any rough edges by sanding the plinth’s surface. Apply paint or varnish according to your liking.

Tips to Help Modify Turntable Plinth

You can always modify the base of your turntable to fit your needs or make it perform its functions better. Here are some helpful tips:

- If the plinth is made of some cheap material, upgrade to a higher quality material for enhanced aesthetics, durability, and effective vibration damping.

- You don’t like the plinth’s dull color or appearance? Apply a different paint or veneer to give it a vibrant touch.

- Reinforce the internal structure of the plinth, adding extra bracing to decrease flex and enhance stability.

- You can customize the plinth by adding custom branding, engraving, or décor to display uniqueness or pay homage to your favorite audio brand.

Leave a Reply